The social responsibility of increasing sustainability is already having an impact on laboratory work today. In addition to ecological harmlessness, this also includes economical working, the greatest possible occupational safety and optimum comfort criteria.

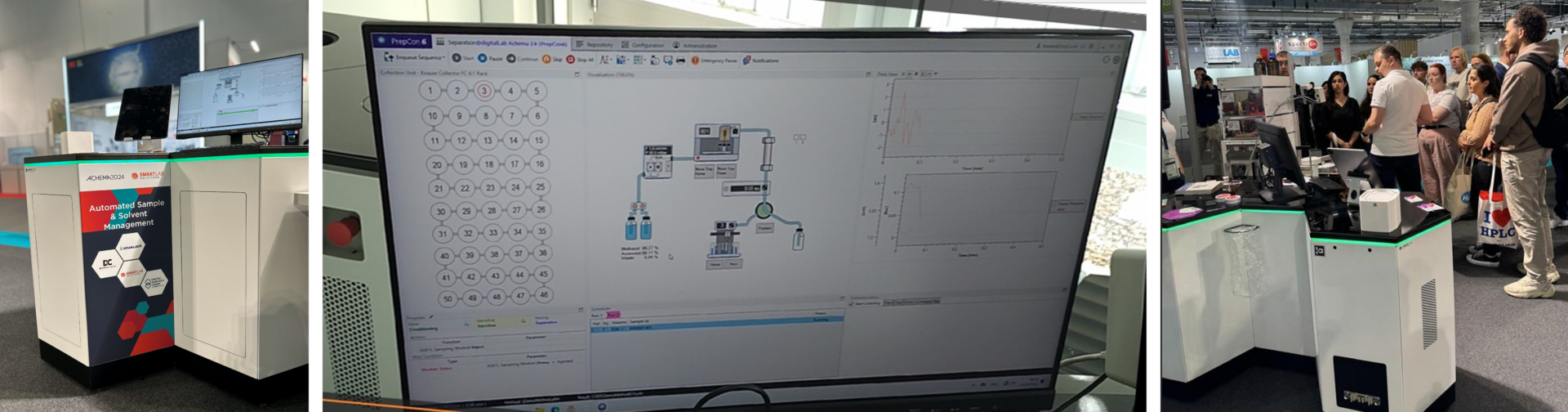

In this use case DÜPERTHAL, KNAUER and SmartLab Solutions jointly developed a sustainable process for preparative HPLC:

KNAUER, a leading manufacturer of liquid chromatography, is renowned for its innovative solutions. PurityChrom, the HPLC control software, offers two new features: i) barcode scanning of vials directly in the rack for automatic sequence insertion, and ii) integrated solvent level monitoring to alert users before chemicals deplete.

Integration with DÜPERTHAL connect, the real-time chemical inventory system, directs users to the storage location of their needed chemicals without the hassle of searching through cabinets for the right quality.

At the HPLC‘s backend, Knauer‘s process control and DÜPERTHAL‘s service station interact. When the waste container nears capacity, chromatography pauses until exchange confirmation, ensuring safety and continuity. Enhanced ventilation and grounding in storage cabinets optimize waste collection.

This HPLC station is integrated into the flexible iHEX laboratory concept by SmartLab Solutions. The autonomous robot KEVIN from the United Robotics Group also supports logistics of samples and solvents. Thus, sustainable HPLC processes are linked with the laboratory of the future.