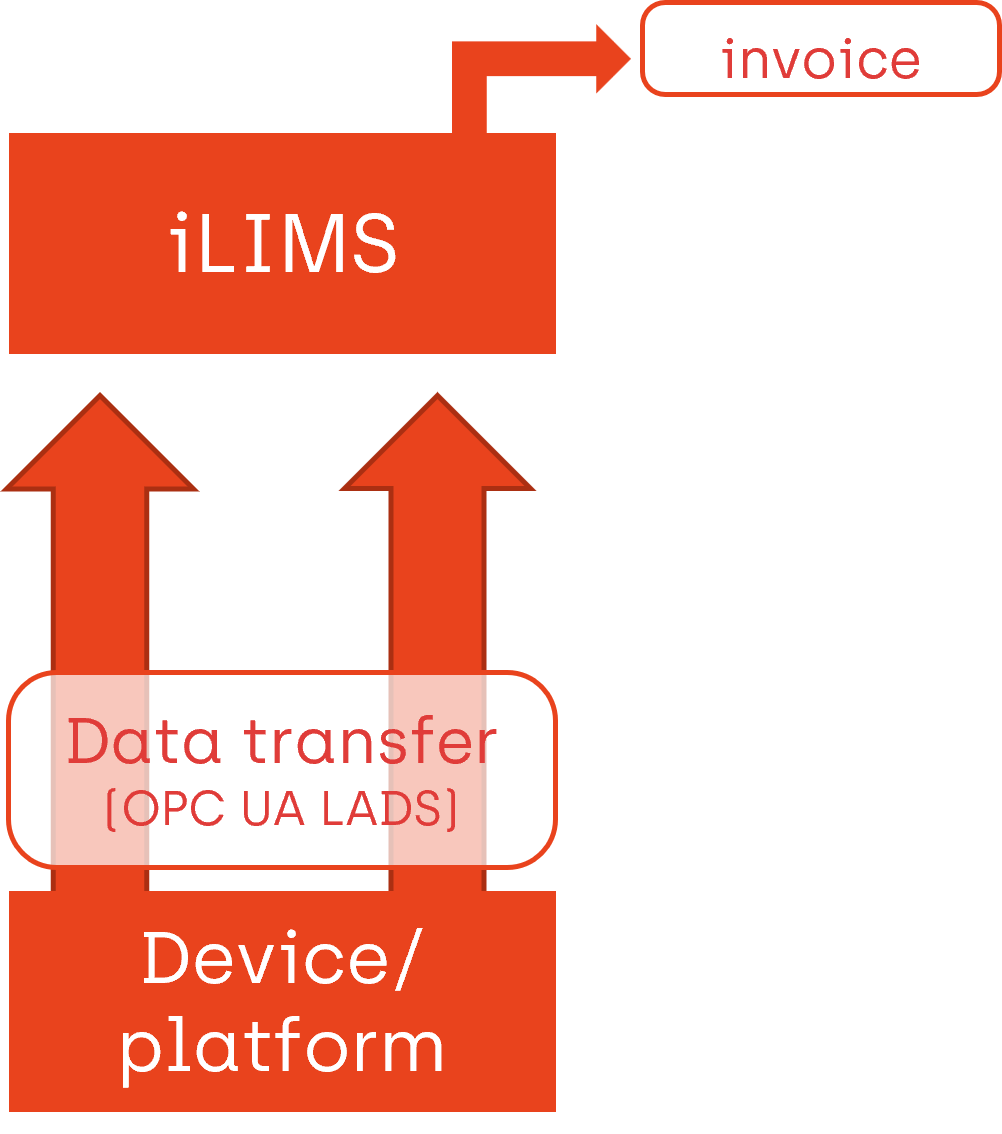

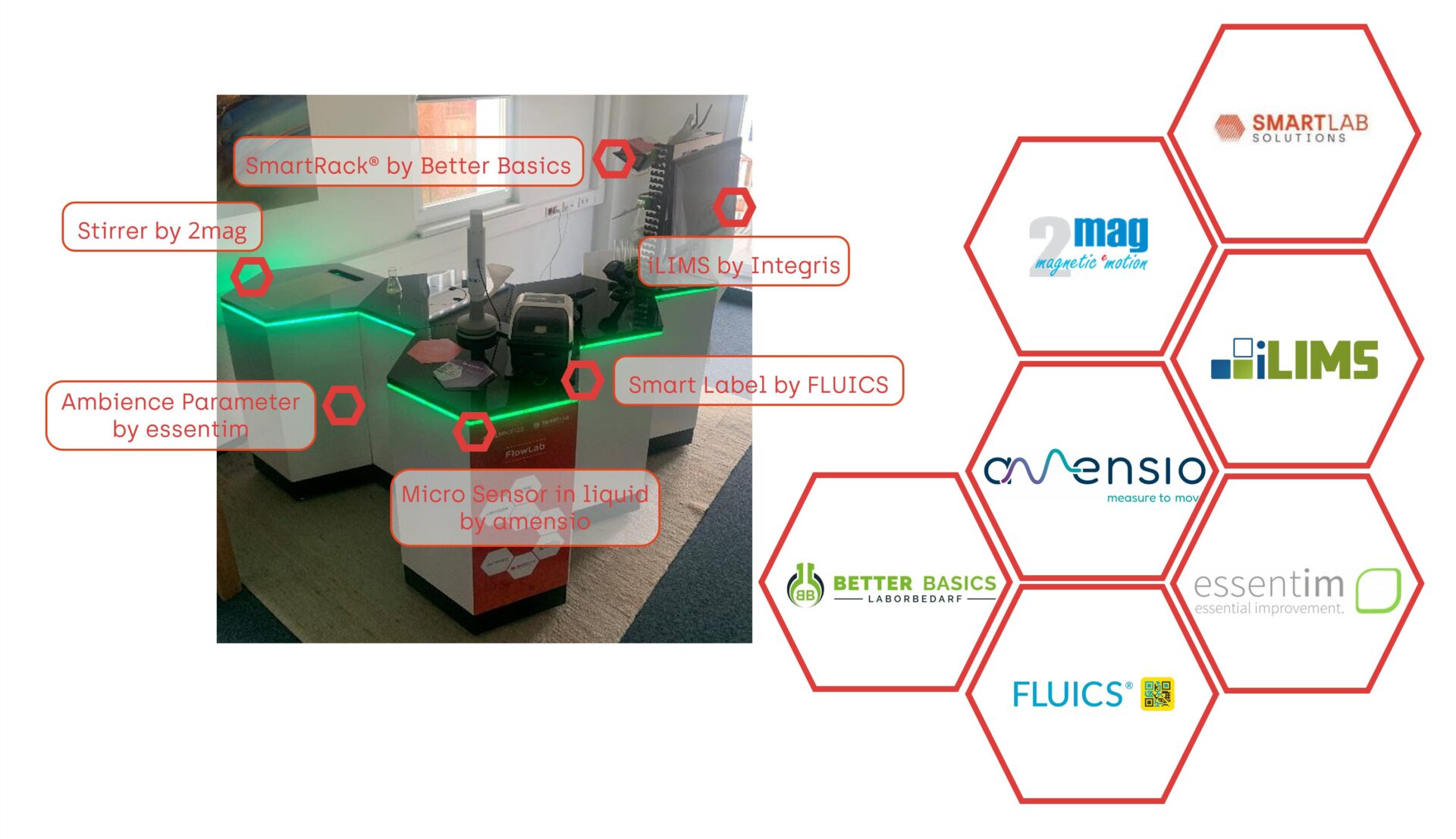

This workflow enables the automated, quality-assured consolidation of all device and sensor data required for laboratory processes directly into the LIMS—from sample receipt to the final invoice. At the same time, users are guided through each workflow step automatically. This reduces time, costs, and the risk of operating errors, such as missed time limits or incorrect process sequences.

In routine laboratories, recording and monitoring a wide variety of parameters is essential. However, consolidating and evaluating this data is often time-consuming and largely manual. This workflow streamlines this effort by harmonizing information automatically and with quality assurance, using the new OPC UA–based laboratory interface LADS (Laboratory and Analytical Device Standard) to transfer data directly into INTEGRIS iLIMS.